Premium packaging

Are you looking for the best and perfect Branded Packaging? If yes, you reached the right place. Our Unique Corporate Gift Ideas are guaranteeing a wow-effect on your Business Clients & Customers.

In giving Business Gifts, you should only trust one of the best to avoid headaches when the time to provide is already there. Walwater Gifts ensures our valued customers the convenience, quality, and excellence in all our aspects of gift-giving.

Request a quote

Each product page indicates a minimum order and customization options. Just add products to the quote and send us a non-binding request.

Receive offer

We will share printing mockups for chosen customization options and an invoice with the costs of production and shipping costs if applied.

Share gifts

Depending on your ordered quantity it might take up to 4 weeks to customize your products. We take care of storing, assembling and shipping.

What makes a packaging premium?

Premium packaging usually features better quality material, colors, and designs, fitting for a higher-end product. It can come in different forms, such as nicer boxes to make your items stand out. “Prices are only one factor that consumers weigh when deciding to purchase something, as many other factors come into play such as the appearance and design.” Consumers today rank the quality of a product on more than just its price. Nowadays, it often comes from the perception of the product’s overall contribution to his or her life.

What is quality packaging?

Packaging testing is performed to ensure that the products’ quality is maintained. It also helps in enhancing the life of the product, as it checks and ensures that the materials used in packaging are strong. This includes quality assurance when producing them. The manufacturer of the product installs the packaging, but to get it out of the factory in a better condition, it must be checked that the product will not be damaged when efficiently packaged. It should be put in a guaranteed and safe bag with good quality materials before being delivered to the customer.

What is good quality packaging?

Packaging is an important aspect of any product and should make it easy to carry, store or to display at the point of sale. When deciding on the size and shape of your package, it is important it be carefully considered by both yourself and your customer. It should be convenient and not too heavy to store in a shop as well as in someone’s home. The size that is given should not be too large or small, which would then make it difficult for others to pack away quickly. So, convenience is a feature of good packaging.

Luxury gift boxes for companies

The luxurious packaging of your products makes them feel like they hold special value. Having elegant and well-designed packaging sets your company apart from other companies in the industry with less-than-stellar marketing. Customers who want high-end products are willing to pay a little more for an experience that makes them feel good about their purchase. So, why not use packaging that matches this emotional appeal?

What are luxury boxes made of? Presentation matters and this is never truer than when it comes to product packaging. Rigid boxes do more than just provide a way of protecting what’s inside; they also make your products look expensive. Generally, larger than folding cartons, rigid (set-up) boxes are made of thick 36 to 120 pt board overlaid with a printed paper wrap.

How do I make my packaging look luxurious?

Use Contrast and Smooth Finishes. Contrast and smooth finishes are one of the most successful luxury packaging ideas. They’re both beautiful to look at and touch, with a contrast between finishes that makes the packaging come alive. One way to achieve this is to use a high-end bag with an embossed design and metallic print like what some luxury brands do. This will make your bags feel luxurious and eye-catching at the same time.

High-End Materials. It is important to use premium quality materials for luxury packaging. It not only looks fancier but also feels nicer in one’s hand. Consumers can tell the difference immediately by touching the packaging. When it comes to high-end packaging, the materials need to be high-end too. Trying to use cheaper materials and trying to make it look like you’re a luxury brand will make your company come across as disingenuous.

Clear and Simple. Luxury products are often thought to be loaded with excess but going for a minimalistic packaging design can actually convey luxury better. Luxury packaging can be as simple as clear, which almost looks like it’s more expensive than a fancy pattern.

Be Authentic. Even with your high-end packaging, you still need to make sure that you’re authentic to your brand. It should reflect what it stands for and be representative of the message you’re trying to send out . With an especially high-end, luxury package, that also comes with a higher price tag. Even with this in mind, it’s important to keep the focus on your brand and be authentic to your ideas and values. The product needs to be of the highest quality possible, though. There are certain instances where you might not want to include all Luxurious packaging that can be simple if that’s what your brand calls for, or more extravagant if needed.

Don’t Compromise Quality

A successful high-end product needs amazing packaging. It’s not enough that just the outside looks great, but the quality should also be excellent on the inside and back. This is how you’ll earn your customer’s trust. If your brand takes shortcuts on packaging, your customers may start to doubt the integrity of the actual product. Ensure your product packaging goes through strict quality control and quality assurance to make sure that customers get the best, safest experience possible.

7 Ways To Create Luxury Packaging

Make It a Mission – Luxury packaging is designed to create an experience for consumers. With high-end products, consumers will be treated as storytellers who should go on a journey of discovering the product.

Add Some Audible Weight -Sound plays more of an important role in retail than many realize. The reason for this is that products tend to sound very similar to one another.

The only way to understand what audible branding can do is to touch a luxury item, like when you gently lift the lid with a creaking hinge or softly rub the crinkled tissue. Generally, it’s low-toned sounds that evoke luxury vibes.

Although there are some exceptions to the rule, you’ll notice that items like cellophane and plastic blister packs are cheap to manufacture & very common. The high-pitched sounds they make can be grating. Heavy, lined boxes are more likely to groan and creak at a lower pitch. It’s one of the reasons paper and cards are preferable for luxury products. Plastic is a rarity for high-end brands.

Give It a Heady Scent – It won’t always be possible to add scents to luxury packaging. However, it’s a handy way to expand the customer experience.

Be Sparing with Bright Colours – The association between bright colors and affordability makes them an ideal marketing tool for companies who want to position their product in the lower end of the market. For more expensive products, be careful not to overdo it with tones that are too bright.

Metallics are a popular choice with luxury brands and they look amazing. When the light reflects on them, they create a mirror ball effect for your eyes to see. Gold and silver are associated with expensive jewelry, so there’s no ignoring the fact they are a sign of wealth.

Let the Packaging Speak – One thing to avoid is using an overbearing logo on your luxury items. Contemporary luxury brands tend not to focus on logos because they want the item’s quality to speak for itself.

Comforting and intelligent things don’t have to shout above everyone else to be noticed. In fact, they don’t want attention at any cost at all. Comforting brands use their intelligence to attract the right feeling toward them.

Consider the Practical Details – This is a difficult step in the process. Commit yourself to design an excellent package and worth your time, effort, and investment. However, the content will be ineffective if it doesn’t stand up to rigorous use.

Get Your Branded Gift Box

Complete the form below for a personalized Merchandise Gift Box quote from our merchandise experts.

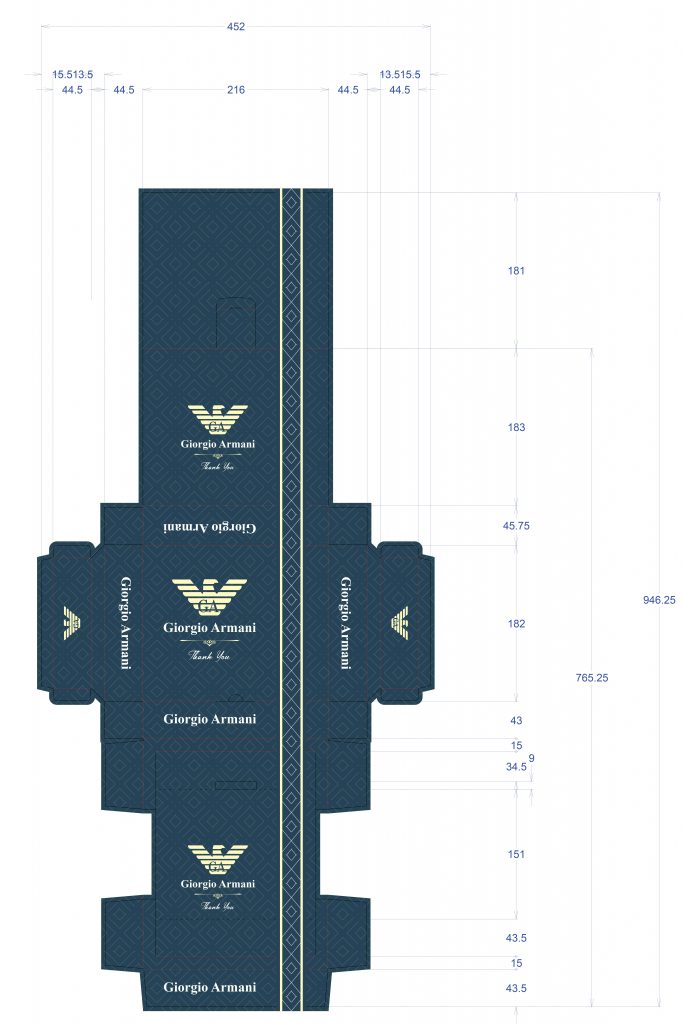

Dieline Design for Packaging

In the industry, “dieline” refers to the cut and fold lines on a piece of packaging. It is used as a template so that the final product can be folded correctly.

What are Dielines used for?

A dieline is a document that explains where the paper needs to be cut, folded, and perforated. This view will send the diagram to your printer in your art files. The design will shape the sheet into a “cookie-cutter” that is used to cut out every printed piece.

In the packaging and printing world, a dieline is a template that ensures the correct placement of design elements. The markings indicate where fold and cut lines should be, and when it is necessary to repeat a design.

Who Creates the Dieline?

Packaging designers typically create die lines through various methods, such as cutting out the design or printing it. Dielines are used in many types of packaging, so it’s safe to say they’re not just for boxes. They can be as simple as folders with pockets or as difficult to create as complex packages. By using dielines, you’re able to cut and fold the material and make a final product.

Types of Lines in the Dieline

Dielines are made up of three types of lines:

A dotted perforation line – Perforated paper features small holes along the lines that can be torn, meaning you can just tear a part of the sheet off instead of cutting or taking care not to make any mistakes.

A cut line is – a line marked on a piece of wood, metal, etc., to indicate where it should be cut

A fold line – The line that the resulting product is folded along is called a folding line.

Dielines on the packaging allow the machines to cut it and fold it so that you can have a more environmentally friendly option. Since these two things are separate “chunks” of information that the printer receives, the perforation lines and cutting lines can appear on different layers and in different colors. This allows the printer to know what to trim and what must be cut.

There is more than one step to take in order to get printed cards, with the perforation process happening at one stage and the cutting happening at another.

Custom food packaging

As you can probably tell by now, if you’re a part of the food production and packaging industry, you already know how important it is to have the right food packaging. The need for good quality food packaging becomes even more apparent when we think about how much it affects what people buy from us. In a globalizing world, food companies are focusing more on their packaging and product preservation for the end customer.

More and more people buy food based on how it looks. To make sure you stand out from the competition, you need to have a custom packaging that tells customers everything they want to know about your product at first glance.

What does food packaging mean?

Packaging is designed to protect the food inside and keep them safe from things like toxins and contamination. The most popular type of packaging that’s used in the food industry often comes in active form.

What is Custom Packaging?

Custom packaging is packaging that is made-to-order for your company and the product you produce. It fits perfectly and protects it from potential dangers that may occur during shipping.

What materials may be used to package food products?

Even though there are different types of materials you can use to create a food-safe label, it is important to understand what your labeling needs are. Is the packaging coming in direct contact with the food? If so, it will be important to use a material, adhesive, and ink chemistry that is food safe.

Types of Food Packaging

Aseptic processing -This process doesn’t just involve sterile equipment, but also sterile products and packages. This is to ensure the safety of all products that are used.

Paper Bags – Paper packaging is a great type of packaging that can not only package and protect your products but also store them. This type of packaging is perfect if you’re in need of lightweight and easy assemble products. Paper packaging is a packaging product made of paper material quite popular on the market today

Boxes – Boxes are a very common type of food packaging. They come in many different materials such as wood, corrugated fiberboard, or metal, enabling them to be more resistant to damage.

Cartons – Corrugated cardboard cartons are great for storing various food products. They come in a variety of designs like other kinds of packaging.

What are the advantages of custom food packaging boxes?

Custom packaging is important for more than just presentation. It can also be used to show your customers what’s inside your product by looking at the label or package.

Building brand awareness – One of the top benefits of custom food packaging is brand awareness. Custom packaging is a great opportunity to show off your products and tell people all about your brand! You want to make the first impression count when customers see your packaging. The details really do matter.

Differentiating your brand – Custom packaging for the food industry embraces the idea of individuality – what makes you different, what sets your foodstuffs apart from competitors? Sometimes adding your logo to products isn’t enough. You need to make it quicker and easier for people to identify your products too! That is why you need to follow a branding strategy and carefully choose packaging designs, color combinations, fonts, visual elements, and materials.

How to make my packaging food more attractive?

If you want to stand out from the crowd and make an impact on your customer, try investment materials like silver foils and holographic foils. They’ll bring you one step closer to achieving high-quality branding that doesn’t come cheap.

Consumers are often drawn to products on the grocery store shelves with brightly colored labels. Think about how this could work for your product!

Adding a foil or varnish to your product name can really make it stand out, e.g. when customers are browsing the store. Varnish will give your labels a raised effect and adding a foil to it will get you that shiny look.

When done professionally, your labels will be the standout decoration at an event. These items typically denote that the product is of higher quality than the others around it with flat black and white labels.

What are the 3 types of packaging?

PRIMARY PACKAGING – Primary packaging is in close contact with the product and its main purpose is to protect and preserve it by sealing it, providing important info about the item, and letting customers know what’s inside of it.

SECONDARY PACKAGING -Secondary packaging is the exterior packaging most often placed around the primary package and it’s sometimes used to group multiple packages or protect them by providing layers of protection. They’re also sometimes used to identify or differentiate different drugs.

TERTIARY PACKAGING -Most of the time referred to as Bulk packaging is used to take larger quantities of items from point A (e.g. production facility) to point B (e.g. point of sale). During this stage, the product is handled and moved around but not placed on the shelf for the consumer to purchase it. It is not just a box of products inside a box. The purpose of Bulk packaging is to reduce the number of interactions between product, retailer, and consumer and increase customer satisfaction by reducing the amount of time it takes to pick out an item on the shelf.

Custom packaging for business

Ensuring that your packaging is up-to-date and ensuring it maximizes customer engagement is vital. It is the first line of defense to help protect your product and the first thing customers will experience when picking out your product from the shelf. When you have a product in a highly competitive industry, packaging could be the very thing that separates a sale for you from a sale for your competitors.

What is Custom Packaging? Customized packaging can help you make a great first impression on new customers and showcase your business in the best light possible. The custom packaging process includes modifying a package’s shape, size, style, colors, material, varnish, and other specifications. Customized packaging is an incredible and cost-efficient way to not only impress your customers but to leave a long-lasting impact on your brand that leads to increased word of mouth, social sharing, brand loyalty and revenue.

The Benefits of Custom Packaging

Improves the Customer’s Experience – People use products every day and we want to make sure that they’re as happy with your product’s packaging as they will be with the product itself. That’s why it’s important to make sure that the packaging is designed thoughtfully, not just for carrying and protecting a product during shipping, but also so it can send a message about the quality. Think of the right packaging as a way to make your product seem exclusive or rare, it will help you reach hesitant customers who want what you have on offer but may not be sure. Be aware that if they don’t feel like they’re getting something exclusive then it’s unlikely they’ll buy what you’re selling.

Allows You to Show Off the Brand – with the option of using a logo or being completely blank. However, there are pros & cons to each approach, so it’s important to take your specific business needs into consideration. Branding is a vital step in the branding process. It helps create a sense of security for customers and allows repeat shoppers to easily find the product again.

Keep Your Product Protected – Custom packaging is great because it ensures that your product arrives in one piece, no matter how odd-shaped or fragile it is. If you’re looking for a sturdy box to protect glassware or something specific to create an exact shape of a shield, you should make protection your top priority.

How to Choose the Right Packaging for Your Products

Pay close attention to the materials you use when packaging your products as they can have a big impact on how good your product looks. For example, a high-quality package may make someone more likely to buy your product.

Important things to consider for producing the best package for your product:

Budget – Before you start any packaging design project, you must determine the scope of your budget. This will help in deciding what materials to use and what design elements to add so as to create a product that appeals greatly to customers.

Materials like glass and natural fibers look terrific and are visually appealing to consumers, but may face durability issues. It can be difficult to ship or store these sorts of products, putting you at risk for increased costs from handling mishaps.

Food-grade cardboard is inexpensive and offers a variety of design options. It also provides protection from bulkier, heavier items while still feeling natural in your hand.

Unfortunately, plastic is not the most environmentally-friendly material, but it’s often recyclable and can be made from recycled materials. It would be a good idea to point that out on the product packaging if you want consumers to feel better about buying your product.

Finding the right balance of what you want to spend on creativity and in production versus what you’ll need to spend on materials will largely affect the success of your project.

Size – If you have a product that comes in different sizes, it’s likely that designing two different package sizes instead of four individual packages will cut costs. However, this will largely depend on the size and exact dimensions you want for each package.

Being creative in this way is cost-saving and will help with the integrity of your products- this is an added bonus that means you will save both time and money. It also helps to guarantee consistency throughout your products.

Design And Branding – You’ll be more successful with package design if you keep your target audience at the forefront of your designs. Getting your package design right is part of building your brand. If you do not put the same care & attention into it as you do with the rest of your branding, people won’t know what to think which will make them lose trust in you. Your customer should be the number one focus of your business. Spend time researching and understanding them before you commit your budget to marketing activities or branding campaigns in order to really sway their minds.

Marke research is an excellent way to learn what your target audience values and decide how to pair those details with your budget. Always listen to the ones that matter the most and match their needs as closely as possible.

Transportation – An exciting design that resonates with your customers and can’t be shipped to the stores for display is a package that’s worthless. If your product is bulky, delicate, or in any kind of unusual shape, you should think about what materials would be appropriate for it.

It’s more cost-effective to invest money upfront in a protective package design than to replace items that have been damaged. Shoot for the middle ground sweet spot between when the cost of product damage equals the cost of a protective package and you will be in good shape to satisfy your production budget as well as your custom.

Materials And Sustainability -E-Commerce packaging is all about convenience for the customer. Some options that have become popular in recent years include bags with different levels of flexibility, so you can pick the one that suits your needs best. They also have easy to open and sealable packages, so you can get them set up with your orders quickly. You will not regret spending some time experimenting with the different materials available out there. Find out which works best for your products and then buy those for the best result.

Factors to Consider When Packaging a Product. Nowadays, packaging needs to be eye-catching. Connect Your Brand Message with Consumers. Your packaging must be clear and concise, according to your target consumers

Most common types of product packaging

Paperboard Boxes – Paperboard boxes are made from a paper sheet that is lightweight but strong. The sheets are either made from recycled waste paper or the fibrous material in wood. It can be manipulated, cut, and folded into various designs and shapes.

Corrugated Cardboard Boxes – Cardboard is usually made of three layers with the two outer layers having a smooth surface and the central inner layer that is corrugated.

Custom Folding Cartons – The foldable design ensures that there are different ways to close up the board, which makes them easy to store. This material is convenient for transporting but also protective of your products due to the coating.

Rigid Boxes – (also called “Set-Up Boxes”) Reusable packaging boxes are becoming more popular and are generally associated with luxury products. Unlike regular folding cartons, they’re not usually printed on directly and they can be used a few times in return for an additional cost.

Poly Bags – Polybags are clear plastic bags made to pack your stuff. It’s usually made out of a material called polyethylene.

Packaging printing options

Lithography or “litho” or “offset” for short – is a planographic printing process where a design is drawn onto a flat metal plate (usually zinc or aluminum). The plate is then affixed with a chemical reaction.

Flexography or “flexo” for short – is a form of rotary printing where ink is applied to various surfaces by means of flexible rubber (or other elastomeric) printing plates. Inks used in flexography dry quickly by evaporation and are safe for contact with food.

Digital – is a process of printing from a digital-based image directly to a variety of media. High-volume and/or large format equipment is used for larger print jobs that are small in run numbers.

Rotogravure or “gravure” for short – is a type of intaglio printing process. Printing is done by engraving the image onto an image carrier, which is either flexible or rigid. Gravure prints are typically made on a cylinder, and it uses a rotary printing press.

Silkscreen or “screen” for short. Screen printing is a type of printing that uses a stencil to block the ink where it’s inaccessible. Ink can then be transferred onto porous surfaces using a mesh to create designs, logos, and more.

Printed sides

Outside Only – Full Color – The ink for printing will only touch the outside of the box.

Inside Only – Full Color -The ink for printing will only touch the inside of the box.

Outside & Inside – Full Color – We will print both the outside and inside of the box.

No Printing (blank) – Your custom box will arrive unmarked.

Coating

Glossy Coating – Glossy coating can make colors more vibrant, but it may also darken them. It protects against scratches and gives your print design a shiny look.

Matte Coating – is a matte paper with a flat, low-gloss surface.

High-Gloss UV Coating – UV coating is a light-resistant, glossy liquid coating that dries on top of the paper. It’s applied during printing and cures with ultraviolet light.

Paper

14 pt. Cardstock -14pt. “Extra thick” paper is a common cardstock for business cards, postcards, and other high-quality print products. The thickness is similar to that of sheets of paper in workbooks – which makes it great for printing cards, postcards, and other firm-like quality print products.

18 pt. Cardstock – 18pt paper is 0.18 inches thick

24 pt. Cardstock – 24-point cardstock is about as thick as 6 sheets of paper. It’s often used for posters, invitations, wall art, and business cards.

Premium White Corrugated Cardboard E-Flute – E Flute Corrugated Cardboard is a paper-based material consisting of a fluted corrugated cardboard sheet and one or two flat linerboards, which can be made of manila or other thick paper.

Premium White Corrugated Cardboard B-Flute – The thinness of the 3mm gives it a lot of versatility. It can be used by itself or paired with other films in different packaging works. They give optimal performance in a variety of packages from die-cutting to regular case-making and more.

How to get custom packaging for big or small businesses?

Running a start-up can be expensive and product packaging makes it difficult to distinguish your company in the marketplace. Your small business product packaging is an investment in your business’s reputation and your future sales growth, especially with the growing focus on eCommerce in today’s world.

If you are looking for small business packaging solutions, consider finding a packaging partner who can offer custom-designed packaging options and other creative packaging ideas.

Creative options like this can help make your brand stand out in the market while generating repeat buyers. Whether you’re in need of creative POP displays or unique custom boxes for small businesses.

Why Custom Packaging For Small Businesses Is Important?

Small business owners often find themselves at a disadvantage when it comes to marketing their products. One of the main challenges is that, as a small business owner, you likely don’t have access to huge marketing budgets like big corporations have. But despite this, there are some things you can do.

Investing in quality custom packaging for your small business products is essential. Rather than getting the ‘cheapest package possible’ you will want to invest in creating a good impression on customers & building trust.

Custom packaging will help to boost your sales, improve your brand awareness, and make your products more visible. It’s a great way to set yourself apart from the competition.

10 Excellent Reasons For Send Gifts In Europe

- We are a European provider with delivery to 25 European countries

We ship our gifts to European Union countries, such as Austria, Belgium, Bulgaria, Croatia, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Luxembourg, the Netherlands, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden.

- Walwater Gifts is an original gifts manufacturer, without a middleman fee

SendGiftsInEurope is an original gifts producer, every gift is hand-made in our warehouse

- We have more than 10 years of experience

For more than 10 years we do our best to keep all our customers happy and satisfied

- Fast delivery

Deliveries throughout the European Union from our warehouse, resulting in faster delivery times

- Low shipping charges

Due to our central location in Europe, we provide low shipping charges for Europe and we guarantee no hidden delivery costs in our prices

- All our Gift Baskets contain well-known trademarks products

Selecting only the finest brands, no supermarket food brands because we believe gift baskets should be something special

- We test all wines and foods before we put them in our gifts

All our wines are tested and approved by the management and the staff (no, we’re not constantly drunk, but a glass or two of wine is perfect for inspiration)

- Branded gifts

Walwater Gifts may offer branded gifts. We can customize the entire gift with your company logo, name, ribbons, and more

- Additional gifts available – add ons

We understand that we cannot always fit all needs which is why we offer additional gifts for each gift basket in our range. Add as many bottles of wine, Teddy bears or other gifts with no extra shipping charges – personalize it! And we have free cards!

- Gift baskets for every occasion

SendGiftsInEurope offers gifts & gift baskets for every holiday and occasion in Europe

Sign Up for exclusive offers

We proudly accept